What is Electrostatic Spraying?

Electrostatic induction, in its simplest form, is a method of harnessing the magnetism generated by static electricity. Today, it is used in many areas, including paint plants, packaging, medical devices, and even wireless charging systems.

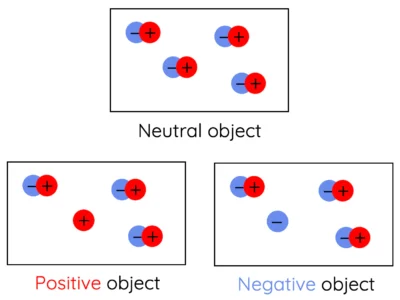

In a very basic definition, all matter in the universe is naturally neutral. When a positive or negative charge changes for any reason, it tends to neutralize itself. We all know this principle from magnets: like poles repel each other, while opposite poles attract each other.

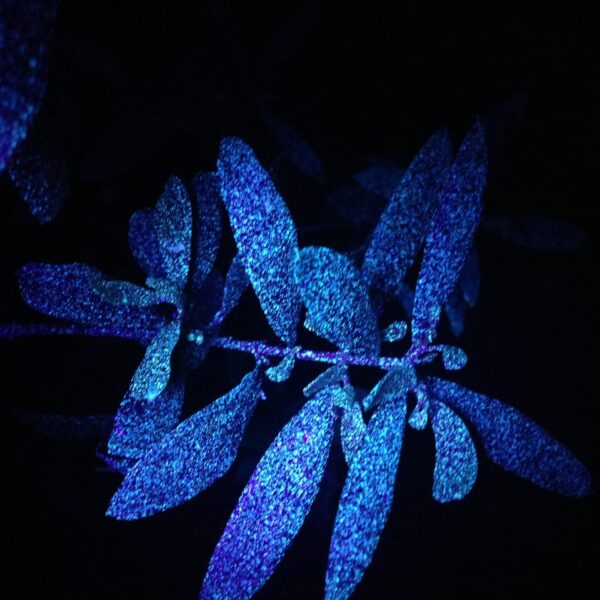

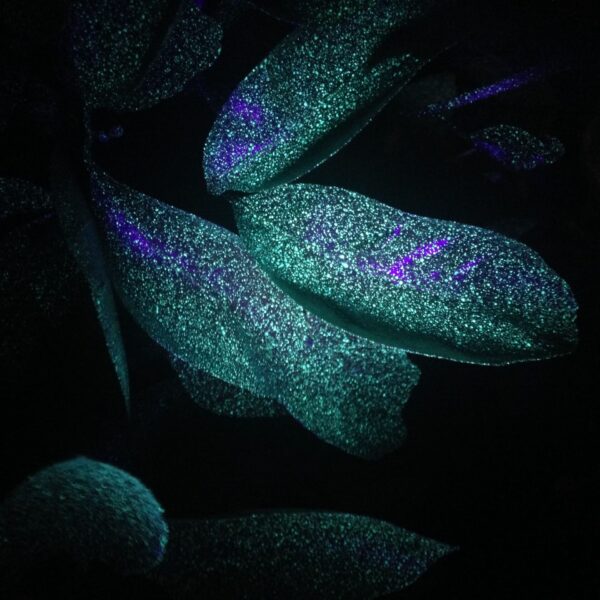

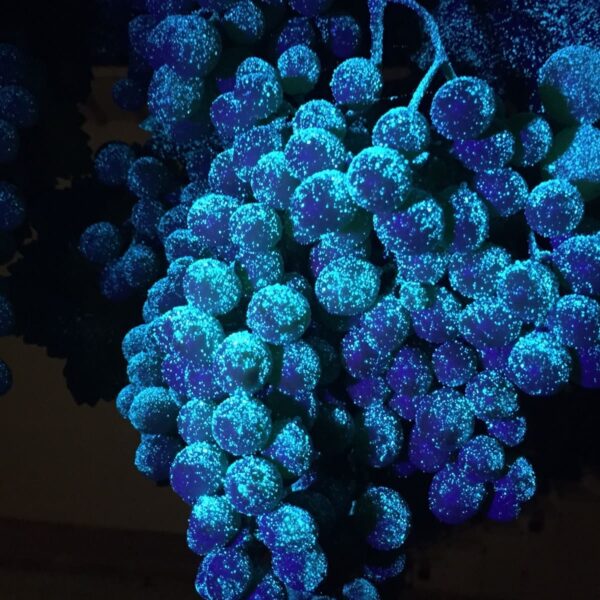

At Boa Makina, we’ve integrated this simple physics principle into our machines to help you achieve more successful applications. Droplets sprayed from the blower are forced through a Faraday cage, disrupting their neutral state and becoming negatively charged. From this point on, they maintain this state until they contact a grounded surface (leaf, fruit, or stem). This charge allows them to adhere much better to the target surface. This is where the electrostatic system truly benefits: each negatively charged droplet, while simultaneously attempting to adhere to the target, repel each other, allowing for a uniform coating on both the front and back of the target without leaving any gaps. This creates a protective film on the target, much like armor, to maximize the effectiveness of plant protection products.

Electrostatic induction is a revolutionary development that has taken the advantages of modern engineering and basic physics principles, while maximizing the benefits of “Low Volume” technology in agricultural spraying applications.

Field studies indicate that BOA HIGH POWER ELECTROSTATIC, even at long distances, has left far behind its competitors by providing excellent induction. As BOA Machinery we are proud to offer you the worlds’ most efficient electrostatic system to the appreciation of our valuable customers.

Another advantage of the electrostatical system, as required by the principles of physics, charged droplets repel each other’s and this effect prevent them from merging into bigger droplets and drop to the ground. BOA HIGH POWER ELECTROSTATIC enables homogeneously coating and allows to reach the best results of spraying.

Electrostatic system maximizes the savings and environmental awareness, thanks to its natural attraction force, by preventing wind-blown droplets.

What is Low Volume?

There are three fundamental principles in crop protection applications:

✅ The Right Active Ingredient

✅ The Right Time

✅ The Right Method

If any of these elements are missing or applied incorrectly, success becomes a matter of chance.

The Low Volume method is the most effective and proven approach among these principles.

What is Low Volume Spraying?

At first glance, Low Volume may seem to mean “applying less liquid,” but in fact, the term describes the result, not the method.

The main principle of this technique is that the sprayed liquid must have the right characteristics to adhere effectively to the target surface.

To fully understand the concept, it’s important to first recognize the limitations of conventional spraying methods.

Limitations of Conventional Systems

In conventional spraying systems, the liquid is forced through narrow nozzles under high pressure.

According to the laws of physics, the liquid must have a certain mass to reach a given distance.

Therefore, in applications for tall trees, the pressure is usually increased.

However, as pressure increases, droplet size also increases;

these large droplets — typically between 350–600 microns — become too heavy to adhere to hydrophobic (water-repellent) plant surfaces.

As a result, even if they reach the target, they cannot stick and run off the surface instead.

Although smaller nozzles are preferred for shorter targets, they tend to clog easily, wear out quickly, and require frequent calibration.

Consequently, growers often need to repeat applications excessively to achieve sufficient coverage.

This leads to:

- 🔴 Significantly higher operational costs

- 🔴 Increased residue risk

- 🔴 Greater hazard to operator and environmental health

Solution: The Right Droplet Size

The key to success is producing droplets in the 50–70 micron range — small enough to reach the target, yet heavy enough to adhere once they do.

This is precisely where Low Volume technology makes the difference.

This drawings indicates, the difference between low volume technology with 50µ level and conventional spraying in 300µ level can be seen clearly.

1 droplet of 300 microns | 27 droplet of 300 microns | 216 droplet of 300 microns

In the illustration above, it is symbolically shown that — based on droplet volume comparison — a single 300-micron droplet can be divided into 216 droplets of 50 microns.

Below are videos from globally recognized crop protection and nutrition manufacturers who have examined this topic in detail.

Working Principle of Low Volume Systems

Unlike conventional sprayers, Low Volume machines use specially designed nozzles with an internal diameter of only 4 mm.

Here, the liquid pressure is just 1 bar (1 atm).

The liquid meets a stream of high-speed, pressurized air passing through specially engineered air channels at the nozzle tip.

This creates a “blast effect,” breaking the liquid into fine droplets sized between 50–70 microns.

Droplets of this size can adhere to plant surfaces effectively, without running off or dripping.

In this system, target delivery is achieved by air volume, not liquid pressure.

Thanks to the high air volume generated by the radial fans, efficient spraying can be achieved even on tall trees where conventional systems fail.

With smaller droplets, the same amount of liquid can cover a much larger surface area — therefore, efficiency and savings are not the goal, but the natural result.

Why Low Volume?

✅ Maximized application efficiency – ensures optimal spray coverage and performance.

✅ Significant savings in chemical, water, time, and fuel consumption.

✅ Improved adhesion on plant surfaces — prevents run-off and dripping.

✅ No liquid pressure, meaning minimal need for calibration and adjustment.

✅ Wide adjustment range, allowing easy adaptation to different crop types and applications.

✅ Optimized air management – air outlets can be configured according to canopy structure.

✅ Low-pressure operation reduces pump and component wear, extending service life.

Limitation

🔺 Pneumatic systems require slightly higher tractor horsepower compared to conventional sprayers.

However, the efficiency, savings, and superior application performance they provide far outweigh this requirement.

Conclusion

🌿 Low Volume technology is one of the most powerful solutions for sustainable agriculture.

With the combination of optimal droplet size, high air volume, and low pressure,

it ensures maximum efficiency in crop protection with minimal resource consumption.

Documents

You can review the documents containing detailed information about our products and the technologies we use.

- Catalog

-

Agricultural Electrostatic

Spray Application - Captan on Strawberries

-

Comparison of Electrostatic

and Coldfog Sprayers -

Electrostatic Biocontrol

Agent Application -

Electrostatic Pesticides

Spraying -

Electrostatic Sprayers

Improve -

Electrostatic University of

Bologna Italy -

Electrostatic University of

Padua Italy